Rotary Offset Printing Machine, Smart-420

(Rotary Label Printing Press)

Smart-420 rotary label printing machine is the combined label printing machine developed by ZONTEN company after 10 years of research and development, which makes up for the gap in domestic high-end printing machines.

As a reliable label printing machine manufacturer with 12 years of offset printing experience, we are deeply aware of the prominence of offset printing process in printing quality, which is unmatched by flexographic printing machines. Now that the printing process is increasingly demanding, low dot gain and printing quality exhibited by offset CMYK 4 primary color overprinting are what customers expect. Therefore, the combined CMYK4 primary color offset printing + spot color flexo printing provided by SMART-420 satisfies customers' unlimited imagination. In addition, the web offset printing press has low ink usage, mature plate-making technology, and low plate costs, allowing customers to save a lot of money in auxiliary materials.

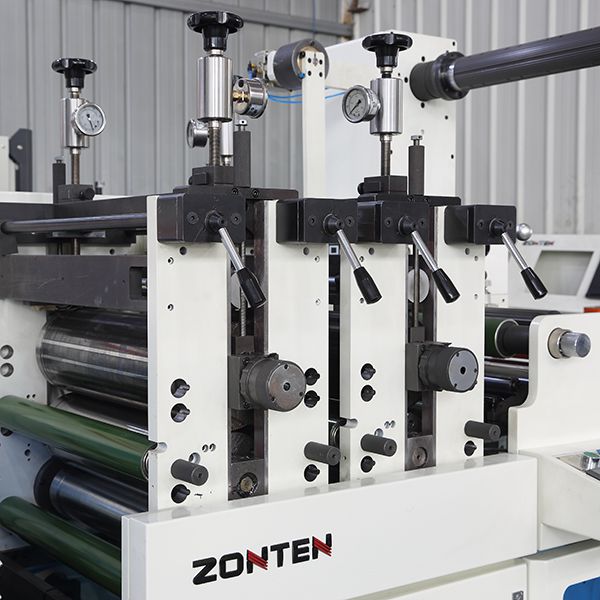

Smart-420 rotary label printing machine is suitable for printing self-adhesive, coated paper, cardboard, aluminum foil and other printing materials. It adopts unit type module combination mode and can be used for 4-12 color printing. Each color group can choose any printing method among offset printing, flexo printing, silk printing and cold stamping.

Smart-420 rotary label printing machine adopts shaftless transmission, equipped with automatic registration system and pre-registration system to ensure accurate registration at high speed (150m/min), optional secondary printing function and front and back printing function, Overprinting is accurate and stable. It is an ideal equipment for printing medium and high-end daily chemical products, wine labels, medicine labels, packaging boxes, self-adhesive labels, etc.

Smart-420 is the first high-end combined offset & flexo interchange printing machine in China. Before that, the only choice for customers was the European and American markets such as nilpeter printing machine.

However, it is well known that the market positioning of nilpeter printing machine is very high-end, and ordinary small and medium-sized enterprises cannot afford the value of its equipment. Only global printing companies like CCL can purchase in large quantities. The introduction of SMART-420 equipment has made up for the gap in the country, while also allowing customers to have more choices.

ZONTEN has spent 10 years devoted to development. Based on the high-end equipment OMET/Nilpeter printing machine in Europe and America, SMART-420 has a more stable ink circuit system, and the machine speed can reach 150 meters per minute. Although the mechanical quality/printing quality is not comparable to the Nilpeter printing machine, we believe that as long as we continue to invest in research and development, we will give SMART-420 more competitive opportunities in the near future.

| Machine Speed | 150m/ min (4-12 color) |

| Max. Print Repeat Length | 635mm |

| Min. Print Repeat Length | 469.9mm |

| Max. Web Width | 420mm |

| Min. Web Width | 200mm (paper), 300mm (film) |

| Max. Print Width | 410mm |

| Substrate Thickness | 0.04 -0.35mm |

| Max. Unwinding Diameter | 1000mm / 350kg |

| Max. Winding Diameter | 1000mm / 350kg |

| Offset Printing Plate Thickness | 0.3mm |

| Flexographic Printing Plate Thickness | 1.14mm |

| Blanket Thickness | 1.95mm |

| Servo Motor Power | 16.2kW |

| UV Power | 6kW*6 |

| Power Supply | 3-phase, 380V±10% |

| Dimensions | 16000×2400×2280mm / 7 color |

| Machine Weight | Offset /flexo 2270kg |

| Weight (others) | Unwinder: 1400kg, die cutter & waste collection: 1350kg, rewinder: 920kg |

-

-

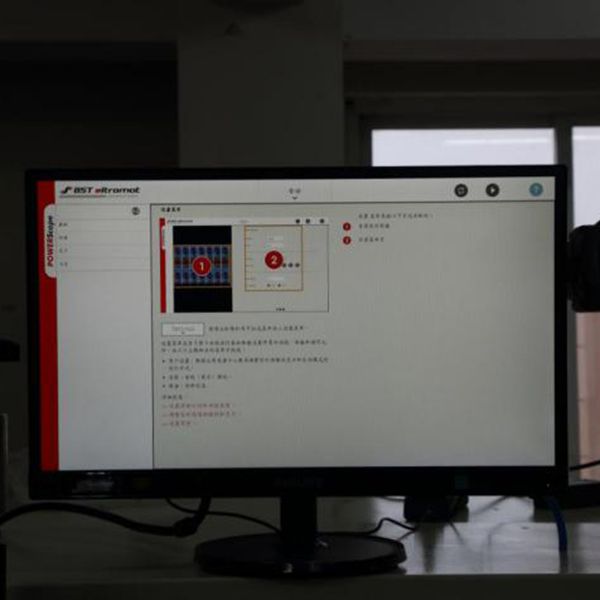

- Centralized control using touch screen: The working parameters can be set and adjusted with the touch screen. The parameters can be stored and memorized, which can be recalled for using anytime. In addition, the process parameters are displayed on the screen to help monitor the whole printing operation in a convenient manner.

-

-

-

- At the top, two corona treatment systems are designed to handle materials on both sides before printing. They are especially suitable for plastic films to increase their surface energy, resulting in improved adhesion of inks. At the bottom, the web cleaner is adopted to remove dust on materials before printing.

-